HACCP Related Content

Implementing HACCP: A Guide for Food Businesses

As a food business owner or manager, implementing an effective …

When it comes to food safety, Hazard Analysis and Critical …

Introduction To eHACCP.org: The Leading Online IHA Accredited HACCP Training Course Provider

Introduction To eHACCP.org: The Leading Online IHA Accredited HACCP Training …

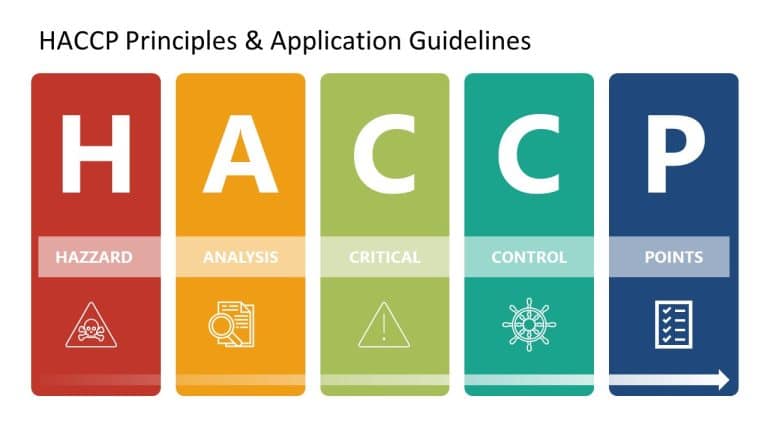

FDA HACCP Principles & Application Guidelines

NATIONAL ADVISORY COMMITTEE ON MICROBIOLOGICAL CRITERIA FOR FOODS The National …

In today’s competitive job market, individuals are constantly seeking ways …

In a world where food safety is paramount, the Hazard …

The Lifesaving Recipe: HACCP and Longevity

Once upon a time, in a small village nestled between …

HACCP Training for: Blender Gasket Maintenance

Blender gaskets can potentially pose a risk if not properly …

In a kitchen, ensuring cleanliness and safety is essential to …

In the realm of food safety and quality assurance, staying …

The origins of the FDA (U.S. Food and Drug Administration) …

HACCP is Climate Friendly

HACCP (Hazard Analysis and Critical Control Points) is a food …