Why Strong HACCP Training Matters More Than Inspections

Food safety is changing faster than ever before. For years, the industry relied mainly on regulatory inspections to catch problems after they occurred. Inspectors would show up, check paperwork, walk through production areas, and point out issues that needed fixing. This approach gradually improved standards, but it was mostly a reaction to things that had […]

HACCP and Food Safety in 2025

We’re looking forward to 2025. 2024 has been a tumultuous year for Food Safety experts. We’ve seen a rise in geopolitical and supply chain disruptions, which are examples of challenges we face in ensuring safe food from farm to fork. The ongoing war in Ukraine and other geopolitical conflicts have significantly disrupted global supply chains, […]

There’s More to the FDA and HACCP Than Warning Letters

The origins of the FDA (U.S. Food and Drug Administration) can be traced back to the late 19th and early 20th centuries when concerns over the safety and quality of food and drugs began to emerge. Prior to the establishment of the FDA, there were limited regulations in place to ensure the safety and efficacy […]

What Are The Prerequisites For Developing A HACCP Plan?

Operations such as regular cleaning and sanitation, and even proper handwashing to avoid cross – contamination, are all part of a bigger food safety program. As the term suggests, prerequisite programs must be satisfied to establish more complex food safety plans such as the Hazard Analysis Critical Control Point (HACCP).

Establishing correct prerequisite programs builds a solid foundation for other food safety plans and shows a firm commitment to protecting public health. These operations can significantly minimize the pressure on implementing food safety plans as the hazards are already addressed in the earlier stages of the production process.

What are the GMPs to HACCP?

GMPs are an important element of a food safety plan and are often used in conjunction with HACCP HACCP is a food safety management system that is used to identify and prevent potential hazards in the food production process, while GMPs focus on the overall cleanliness and operation of the facility.

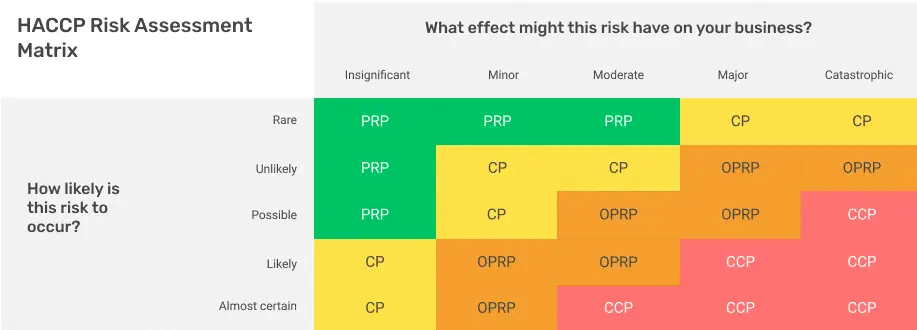

What is a Hazard Assessment in a Food Safety Plan?

A hazard assessment is an important step (Principle 1 of your HACCP plan development) in developing a food safety plan. It involves identifying and evaluating potential hazards that may be present at different stages of the food production process, from raw material production to final product distribution. The goal of the hazard assessment is to identify and prioritize the hazards that are most likely to occur and that have the greatest potential to cause harm, so that appropriate preventive controls can be implemented to reduce the risk of these hazards.

What is PCQI Training?

PCQI stands for Preventive Controls Qualified Individual. It is a training program designed to provide individuals with the knowledge and skills to develop and implement a food safety plan to comply with the U.S. Food and Drug Administration’s (FDA) Current Good Manufacturing Practices (cGMP) and Hazard Analysis and Risk-Based Preventive Controls (HARPC) requirements. The PCQI […]