The food manufacturing industry is rapidly evolving due to huge steps in technological / industrial growth in monitoring and global supply chain complexities, the ageless structure of Hazard Analysis and Critical Control Points (HACCP) remains crucial. HACCP was established by NASA and Pilsbury in the 1960s and refined by the FAO’s Codex Alimentarius standards, HACCP ensures food safety by proactively identifying and controlling hazards. Consumer demands for transparency and sustainability are rising.

This post serves as an educational paper, breaking down HACCP’s 12 foundational steps (including preliminary preparations) and its core 7 principles, tailored to today’s food manufacturing landscape. Each section includes relatable scenarios to illustrate real-world application, empowering manufacturers, regulators, and consumers alike. From small artisanal producers to high-tech factories, HACCP isn’t just compliance it’s the blueprint for safer, smarter food production.

For more resources, including accredited online HACCP training, visit eHACCP.org.

The 12 Steps of HACCP: Building a Robust Food Safety System

Developing fundamental prerequisite programs (PRPs) is a key and an absolute requirement to building an effective Hazard Analysis and Critical Control Points (HACCP) plan with the goal of preventing foodborne illnesses, ensuring regulatory compliance, and protecting consumers. A common mistake companies make is jumping straight into HACCP without first establishing solid foundational controls. This is where Prerequisite Programs (PRPs) come in.

Prerequisite Programs are the essential building blocks of any effective food safety system. According to authoritative sources like the FDA, USDAFSIS, and Codex Alimentarius, PRPs provide the basic environmental, operational, and hygienic conditions necessary to produce safe, wholesome food. They include practices such as:

- Current Good Manufacturing Practices (cGMPs)

- Sanitation and cleaning procedures

- Pest control

- Personal hygiene and employee training

- Facility design and maintenance

- Supplier approval and raw material control

- Allergen management

Once the majority of the PRPs have been assembled you can now move onto the HACCP plan.

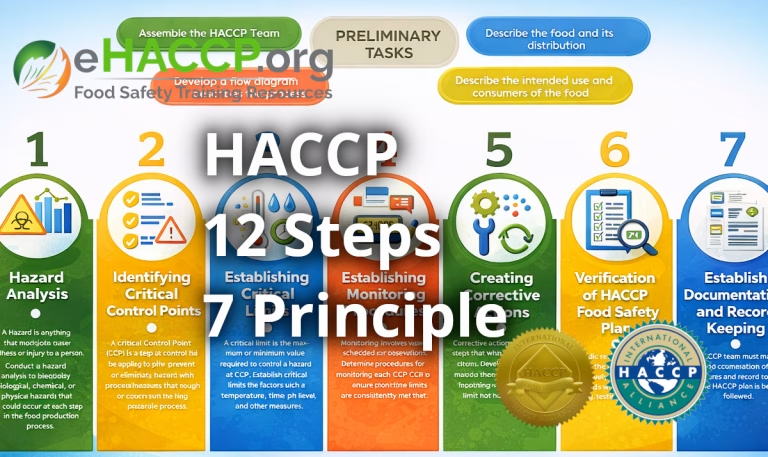

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to identifying, evaluating, and controlling food safety hazards. There are 12 steps and 7 principles to HACCP. The 7 Principles are made up of the last 7 steps. You’ll see…

Let’s begin.

HACCP Step 1: Assemble the HACCP Team

Like all good beginnings we’ll start at Step 1, “Assemble the HACCP Team”. This is the foundational step where a multidisciplinary group is formed to develop and implement the HACCP plan. This team brings together diverse expertise to ensure a comprehensive understanding of the production process, potential hazards, and control measures. The team should include individuals with knowledge in areas like production, quality assurance, sanitation, engineering, and food safety regulations. Ideally, the team is small (typically 4-6 members) to facilitate efficient decision-making, but it can consult external experts if needed. It is required that at least one team member is trained and certified in HACCP having taken a HACCP course accredited by the International HACCP Alliance (IHA).

The importance of this step lies in leveraging collective knowledge to help in preventing repeating mistakes, avoid oversights, ensure better decision-making, prevent knowledge loss, and foster innovation. A well-assembled team ensures that the HACCP plan is practical, tailored to the operation, and compliant with standards like those from the FDA or Codex Alimentarius. Without a strong team, the plan might miss critical hazards, leading to food safety risks, recalls, or regulatory violations.

- Identify key roles: Select members based on their direct involvement in the bakery’s operations. Include a mix of management, technical, and frontline staff for balanced perspectives.

- Ensure multidisciplinary input: Cover expertise in microbiology, chemistry, engineering, and process flow. If internal expertise is lacking (e.g., in allergen control), involve external consultants like a food safety auditor.

- Train the team: All members should receive basic HACCP training to align on principles.

- Designate a leader: Appoint a HACCP coordinator (often from quality assurance) to guide meetings and documentation.

- Document the team: Record members’ names, roles, qualifications, and responsibilities in the HACCP plan for traceability.

Scenario Using Oliviam Breads Bakery as an Example

Oliviam Breads is a mid-sized artisan bakery, located in the Mid West, specializing in sourdough loaves, pastries, and gluten-free options. They produce items like olive-infused bread, croissants, and muffins using ingredients such as flour, yeast, nuts, and dairy. The bakery operates in a single facility with mixing, proofing, baking, cooling, and packaging stages. To implement HACCP, the owner decides to assemble a 5-person team to address hazards like microbial contamination (e.g., from raw flour), allergens (e.g., nuts), and physical contaminants (e.g., metal from equipment).

Here’s how Step 1 unfolds in a practical scenario at Oliviam Breads:

Initial Assessment and Team Formation:

- The bakery owner recognizes the need for HACCP after a minor incident where a batch of nut-containing muffins was cross-contaminated with a nut-free line, leading to a customer complaint. To prevent escalation, they initiate HACCP starting with team assembly.

- The owner reviews staff qualifications and selects 5 members based on their roles and expertise. The team meets weekly for 2 hours to brainstorm and document.

The 5-Member HACCP Team at Oliviam Breads:

Team Leader: Maria Oliviera (Owner and Bakery Manager)

- Role: Oversees overall operations and ensures the HACCP plan aligns with business goals.

- Expertise: 15 years in bakery management, knowledgeable in product recipes and regulatory compliance (e.g., FDA food safety rules).

- Contribution: Provides high-level oversight and resources; facilitates team meetings.

Quality Assurance Specialist: Jamal Patel

- Role: Handles daily quality checks and testing.

- Expertise: Certified in food safety (e.g., ServSafe), experienced in hazard identification like allergen testing.

- Contribution: Leads hazard analysis, ensuring controls for chemical hazards (e.g., cleaning agents) and biological risks (e.g., Salmonella in flour).

Production Supervisor: Elena Ruiz

- Role: Manages the baking floor and staff shifts.

- Expertise: Hands-on knowledge of process flow, from dough mixing to packaging, including equipment operation.

- Contribution: Identifies operational bottlenecks, such as potential cross-contamination during ingredient handling.

Sanitation Coordinator: Tomas Chen

- Role: Oversees cleaning protocols and pest control.

- Expertise: Trained in sanitation chemistry and microbial control, with experience in verifying cleaning efficacy.

- Contribution: Focuses on preventing hazards like mold growth in humid proofing areas or pest infestations in storage.

Maintenance Engineer: Sophia Grant

- Role: Maintains ovens, mixers, and conveyor systems.

- Expertise: Engineering background, skilled in equipment calibration and preventive maintenance to avoid physical hazards (e.g., broken sieves introducing metal fragments).

- Contribution: Advises on engineering controls, like installing metal detectors at critical points.

Practical Scenarios in Action:

Scenario 1: Addressing a New Product Launch: Oliviam Breads plans to introduce a vegan pastry line. During team assembly, Maria (leader) calls an initial meeting where Jamal (QA) highlights potential allergen risks from shared equipment. Elena (production) describes the process flow, Tomas (sanitation) suggests enhanced cleaning protocols, and Sophia (maintenance) recommends equipment modifications. The team collaboratively maps out hazards, ensuring the new line doesn’t compromise existing safety.

Scenario 2: Responding to a Supplier Issue: A flour supplier reports a potential E. coli contamination. The team convenes urgently. Jamal analyzes lab tests, Elena reviews receiving procedures, Tomas checks storage sanitation, Sophia inspects sieving equipment, and Maria coordinates a hold on affected batches. This quick response prevents a recall, demonstrating the team’s value in crisis management.

Scenario 3: Routine Review and Training: Six months into HACCP implementation, the team reviews the plan. They identify a gap in staff training on handwashing. Tomas leads a workshop, using real bakery examples like dough handling to make it practical. This ensures ongoing compliance and adapts the plan to seasonal changes, like increased humidity in summer affecting mold risks.

By assembling this team, Oliviam Breads creates a robust foundation for the remaining HACCP steps (e.g., hazard analysis in Step 2). In practice, the team should reconvene periodically to update the plan based on audits or changes in operations. If your bakery has unique aspects (e.g., organic sourcing), adjust team composition accordingly for relevance.

HACCP Step 2: Describe the Product

In HACCP, Step 2 requires the HACCP team to create a clear and detailed description of each product (or product group) covered by the HACCP plan. This step provides the essential context needed for accurate hazard analysis in later steps. Without a thorough product description, the team might miss hazards related to ingredients, processing, packaging, storage, or intended use.

The product description typically includes:

- Common name

- Ingredients list (with quantities or percentages where relevant)

- Physical/chemical characteristics (e.g., pH, water activity/aw, shelf life)

- Packaging type

- Storage and distribution conditions

- Shelf life and date coding

- Target consumers (including any vulnerable groups)

- Intended use (e.g., ready-to-eat, requires cooking)

- Any special handling instructions

This information is usually documented in a formal product specification sheet, a simple but accurate document that becomes part of the official HACCP records.

Here are practical, relatable scenarios using Oliviam Breads, the artisan bakery from our previous example. The bakery produces three main product groups: sourdough bread, butter croissants, and gluten-free muffins.

Here are examples of how the HACCP team (Maria, Jamal, Elena, Tomas, and Sophia) might describe these products in real life:

Classic Olive Sourdough Loaf (Ready-to-Eat Artisan Bread)

This is one of Oliviam Breads’ flagship items, a naturally leavened, long-fermented bread with kalamata olives folded in.

Here are some real-world photos of similar freshly baked artisan sourdough loaves to give you a sense of the product:

Product Description (as documented by the team):

- Common name: Olive Sourdough Loaf

- Ingredients: Organic bread flour, water, sourdough starter (flour + water), kalamata olives (10%), sea salt

- Key characteristics: pH ≈ 4.2 – 4.6, water activity (aw) ≈ 0.96, final internal temperature ≥ 96°C during baking

- Packaging: Loose in paper bag (for in-store) or perforated plastic bag (for wholesale)

- Storage & distribution: Ambient temperature (18 – 24°C), cool and dry; avoid direct sunlight

- Shelf life: 4 – 5 days at room temperature (best within 3 days for optimal texture)

- Intended use: Ready-to-eat; may be sliced/toasted by consumer

- Target consumers: General population (no specific vulnerable groups)

- Special notes: Contains wheat (gluten); olives may introduce pit fragments (physical hazard)

Scenario: During a recent customer complaint about a “hard object” in the bread, the team used this detailed description to quickly trace the issue to an olive pit thus reinforcing the need to emphasize manual pit removal in the hazard analysis.

Classic Butter Croissants (Laminated Pastry)

These are flaky, buttery French-style croissants sold fresh daily.

Product Description (as documented):

- Common name: Butter Croissant

- Ingredients: Wheat flour, European-style butter (25 – 28%), water, sugar, yeast, salt, egg wash

- Key characteristics: pH ≈ 5.8 – 6.2, aw ≈ 0.92, baked to golden color with internal temp ≥ 88°C

- Packaging: Individual paper sleeve or open bakery display case

- Storage & distribution: Ambient (18 – 24°C); best consumed within 24 hours

- Shelf life: 1 – 2 days maximum (texture deteriorates rapidly)

- Intended use: Ready-to-eat breakfast/snack item

- Target consumers: General population

- Special notes: High butter content > potential allergen (milk); contains egg (allergen); laminated dough increases risk of allergen cross-contact if shared equipment is used.

Scenario: When launching a new chocolate-filled version, the team realized the original description didn’t account for the addition of chocolate (a potential allergen for some). Updating the description helped identify the need for dedicated filling equipment to prevent cross-contact with plain croissants.

Gluten-Free Blueberry & Almond Muffins

A popular item for customers with dietary restrictions.

Product Description (as documented):

- Common name: Gluten-Free Blueberry Almond Muffin

- Ingredients: Gluten-free flour blend (rice, potato, tapioca), almond flour (12%), fresh blueberries, eggs, sugar, vegetable oil, baking powder, salt

- Key characteristics: pH ≈ 6.5 – 7.0, aw ≈ 0.88, baked to internal temp ≥ 93°C

- Packaging: Individual paper liner + clamshell or bakery box (labeled “GLUTEN-FREE”)

- Storage & distribution: Ambient (18 – 24°C); refrigerate for extended life

- Shelf life: 5 – 7 days at room temperature; 14 days refrigerated

- Intended use: Ready-to-eat

- Target consumers: General population and individuals with celiac disease/gluten intolerance

- Special notes: Contains almonds (tree nut allergen); produced on dedicated GF line to prevent cross-contamination; labeled with “May contain traces of wheat” due to facility-shared environment.

Scenario: A new customer with severe celiac disease asked about production practices. The detailed product description allowed the team to confidently explain the dedicated mixing area and color-coded tools, building trust and preventing a potential serious health incident.

HACCP teams often use simple tables or forms like these to document product descriptions consistently.

In practice at Oliviam Breads, the team keeps one master document per product group, reviews it annually (or when recipes change), and references it constantly during hazard analysis, CCP determination, and verification activities. This simple but powerful step ensures the entire HACCP plan is built on accurate, shared understanding of what the bakery factually makes and sells.

HACCP Step 3: Identify Intended Use

In HACCP, Step 3 requires the team to clearly define how the product is intended to be used by the end consumer, including who the typical users are and any reasonably foreseeable misuses. This information is critical because it directly influences hazard identification and severity assessment in Step 4 (Hazard Analysis). For example:

- Products eaten without further cooking (ready-to-eat) carry higher risk for biological hazards like pathogens surviving to consumption.

- Products aimed at vulnerable groups (infants, elderly, immunocompromised) require stricter controls.

- Foreseeable misuses (e.g., eating raw dough) must be considered even if not the intended use.

The intended use is usually documented as a short, clear statement in the product description or as a dedicated section. It answers questions like:

- Is it ready-to-eat (RTE) or does it require cooking/heating?

- Who is the target consumer?

- Are there any special instructions (e.g., “refrigerate after opening”)?

- What are realistic ways consumers might misuse it?

Continuing with our example bakery Oliviam Breads, here’s how the HACCP team (Maria, Jamal, Elena, Tomas, and Sophia) documented the intended use for their three main product groups, along with practical, relatable scenarios.

Classic Olive Sourdough Loaf

Intended Use Statement (as documented):

- Ready-to-eat (RTE) product.

- Typically consumed as-is, sliced and eaten plain, with butter, dipped in oil, or used for sandwiches.

- Target consumers: General healthy population (adults and older children).

- Reasonably foreseeable misuse: Eating very fresh/warm loaf immediately after purchase (common in artisan bakeries) or consuming beyond best-before date when mold may develop.

Practical Scenario:

A local café buys the sourdough in bulk to make avocado toast. During a routine review, Jamal (QA) points out that the café sometimes serves it untoasted to customers who request “soft bread.” The team realizes this is a foreseeable use and adds a note about ensuring proper baking temperature controls, since toasting is not relied upon to kill potential pathogens.

Classic Butter Croissants

Intended Use Statement:

- Ready-to-eat (RTE) breakfast or snack pastry.

- Consumed at room temperature or slightly warmed; no further cooking required.

- Target consumers: General population (adults and children).

- Reasonably foreseeable misuse: Children eating the croissant straight from the bag without supervision (possible choking hazard from flaky layers) or leaving it out all day in warm weather.

Practical Scenario:

During summer farmers’ market sales, Elena (Production Supervisor) notices many families buying croissants for kids to eat immediately while walking around. The team discusses the high butter content and flaky texture as a potential choking risk for very young children. They decide to add a small caution sticker (“Best for ages 4+; supervise young children”) and strengthen allergen labeling visibility – a direct outcome of carefully defining intended use and misuse.

Gluten-Free Blueberry & Almond Muffins

Intended Use Statement:

- Ready-to-eat (RTE) snack or breakfast item.

- Consumed as-is at room temperature.

- Target consumers: General population plus individuals with celiac disease, gluten intolerance, or wheat allergy.

- Special consideration: Must be treated as suitable for highly sensitive gluten-intolerant consumers.

- Reasonably foreseeable misuse: Cross-contamination by consumers who store it next to wheat-containing products at home.

Practical Scenario:

A customer with celiac disease emails to ask if the muffins are safe for her teenage daughter who is newly diagnosed. Maria (Owner) refers to the documented intended use and confidently explains the dedicated gluten-free production area, separate tools, and thorough validation testing. This clear documentation turns a potentially anxious inquiry into a loyal repeat customer. Had the team not explicitly stated the intended consumer group, they might have given a vague answer and risked serious health consequences.

Step 3 is short but extremely powerful – it forces the team to think like the customer from the very beginning. At Oliviam Breads, revisiting intended use whenever they add a new product or change packaging has helped prevent several potential food safety issues before they ever reached the shelf.

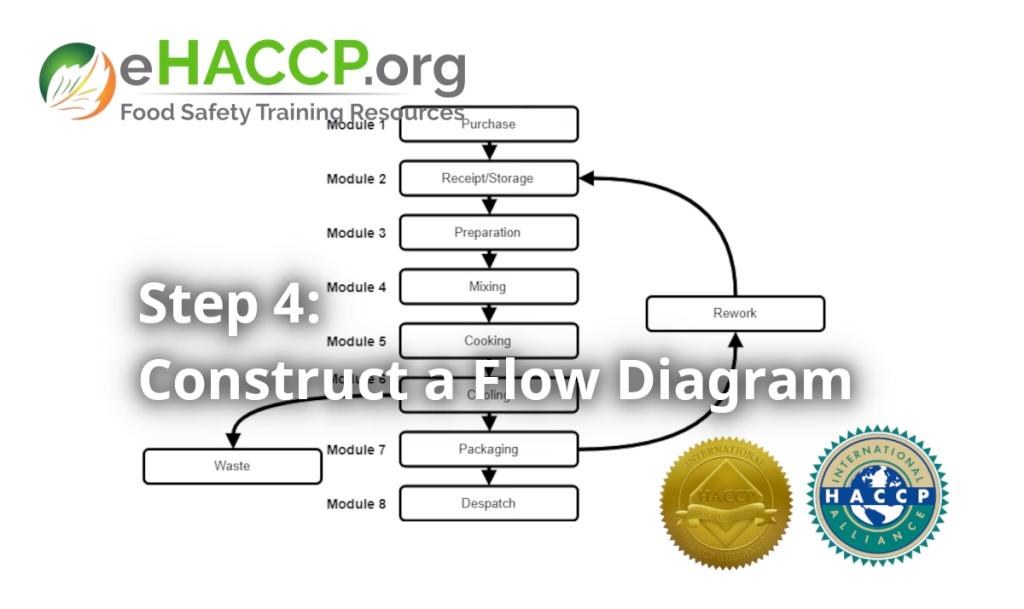

HACCP Step 4: Construct a Flow Diagram

In HACCP, Step 4 involves creating a clear, accurate flow diagram (also called a process flow chart) that visually maps every step in the production of the product – from receiving raw materials to the point the product leaves the bakery’s control (e.g., shipping to customers or retail display).

The flow diagram must be:

- Simple and easy to understand (boxes/arrows are common)

- Sequential (shows the real order of operations)

- Comprehensive (includes all steps, even seemingly minor ones like weighing or temporary storage)

- Verified on-site (the team physically walks the process to confirm nothing is missing)

This diagram becomes the backbone for Step 5 (On-site confirmation) and Step 6 (Hazard analysis), because hazards can only be identified accurately if you know exactly where and how they might occur.

At Oliviam Breads, the HACCP team (Maria, Jamal, Elena, Tomas, and Sophia) creates one flow diagram per major product group, then verifies it by walking the bakery floor together.

Classic Olive Sourdough Loaf – Flow Diagram Overview

The team drew a straightforward linear flow for this artisan product (long fermentation makes it unique).

Practical Scenario: During the first on-site verification walk, Elena (Production Supervisor) noticed they had forgotten to include “manual olive pitting & sorting” before folding them into the dough. Adding this step revealed a potential physical hazard (olive pits), which the team later controlled with a sieve and visual inspection, a direct result of having an accurate flow diagram.

Classic Butter Croissants – Flow Diagram Overview

Laminated pastries have more complex steps due to repeated folding and resting.

Key Steps in the Croissant Flow (simplified):

- Receipt of ingredients (flour, butter, yeast, etc.)

- Dough preparation (détrempe)

- Butter block preparation

- Lamination (multiple folds & rests)

- Sheeting & cutting

- Shaping & proofing

- Egg wash

- Baking

- Cooling

- Packaging

Practical Scenario: When the team reviewed the flow diagram for a new almond-filled croissant variant, Sophia (Maintenance Engineer) pointed out that the shared sheeting line could introduce nut residue. The diagram helped everyone visualize the shared equipment step, leading to a decision to schedule dedicated “nut-free” runs with full cleaning verification in between.

Gluten-Free Blueberry & Almond Muffins – Flow Diagram Overview

Because this is a dedicated gluten-free line, the flow emphasizes segregation.

Typical Flow Diagram Steps:

- Receipt of GF ingredients (separate storage)

- Weighing/mixing (dedicated GF area)

- Batter resting

- Depositing into liners

- Baking

- Cooling

- Packaging with clear “GLUTEN-FREE” labeling

- Storage/distribution

Practical Scenario: A new employee accidentally used a shared scale for gluten-free flour. When the team later reviewed the flow diagram, Jamal (QA) highlighted the “weighing” step and recommended color-coded, dedicated scales for the GF line. The diagram made it obvious where the control was needed, preventing future mix-ups.

Quick Tip: How the Team Documents & Verifies

Many small bakeries start with hand-drawn sketches on large paper, then digitize them. The whole team walks the actual production process (“line walk”) while holding the diagram, marking any missing steps or shortcuts.

Step 4 is all about accuracy and teamwork and if the diagram doesn’t match reality, the entire hazard analysis will be flawed. At Oliviam Breads, updating the flow diagrams whenever equipment changes or new products are added has become a routine part of continuous improvement.

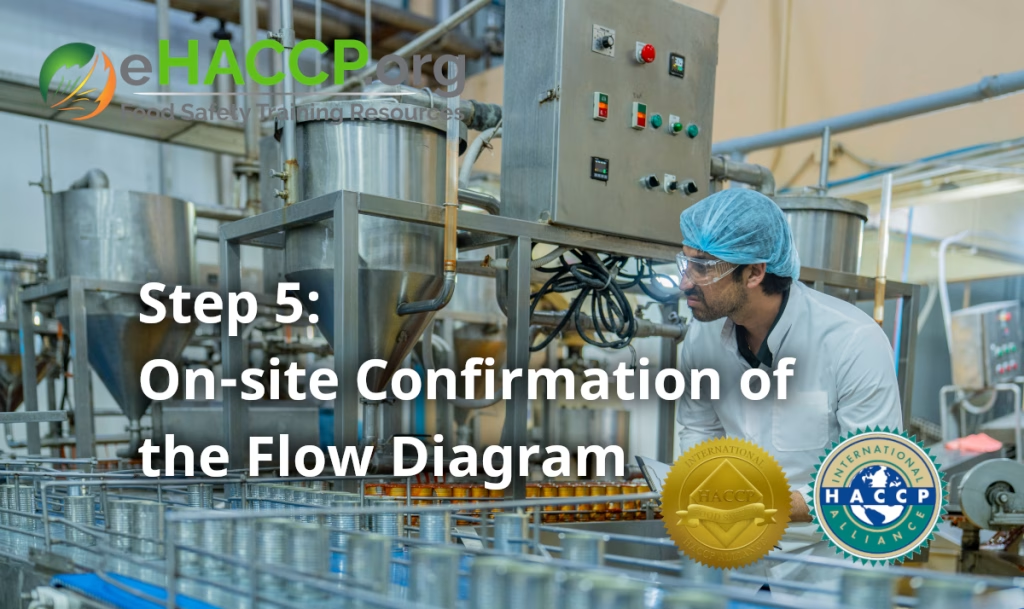

HACCP Step 5: On-site Confirmation of the Flow Diagram (also known as On-site Verification of the Flow Diagram)

In HACCP, Step 5 is the critical reality check: the entire HACCP team physically walks through the bakery’s production process exactly as it happens to confirm that the flow diagram created in Step 4 accurately reflects real operations. This step is often called the “line walk” or “process walk-through.”

Why it’s essential:

- People write flow diagrams based on memory, procedures, or “how things are supposed to be.”

- In real life, shortcuts, seasonal changes, new equipment, or undocumented steps often exist.

- Any missing or incorrect step in the diagram means hazards could be overlooked during analysis, leading to an ineffective HACCP plan.

The team must:

- Walk the entire process from start (receiving) to end (packaging/storage/shipping).

- Observe actual operations (not just talk about them).

- Note any differences between the diagram and reality.

- Update the flow diagram immediately if discrepancies are found.

- Do this during normal production hours when possible (to see real practices).

- Repeat periodically (e.g., annually) or after significant changes.

Continuing with Oliviam Breads, here’s how the team (Maria the owner/manager, Jamal QA, Elena production supervisor, Tomas sanitation, Sophia maintenance) carries out this step for their main products, with practical, relatable scenarios.

Olive Sourdough Loaf – On-site Confirmation in Action

The team starts at the receiving dock and walks through the entire process.

What they discovered during the walk:

- The diagram showed “olives added during final shaping,” but in reality, Elena’s team pitted and folded olives in during the second fold to improve even distribution (a better technique they adopted 6 months ago but never updated).

- They also noticed a temporary holding step for dough portions in plastic bins during busy periods when the proofing room was full – not on the original diagram.

Practical Scenario:

During the walk, Tomas pointed out that the cooling racks were sometimes moved too close to an open door on hot days, creating a risk of airborne contaminants. This observation led to adding “controlled cooling area” as a formal step and a note about door management. Without the physical walk, this hazard would have been invisible on paper.

Butter Croissants – A Surprising Shortcut Revealed

Lamination is time-consuming, so the team expected to see the full schedule of folds and rests.

Key finding from the walk:

- On double-shift days, the night crew sometimes reduced one rest period by 10 minutes to keep up with orders. This shortcut was not documented anywhere.

- The butter block preparation happened in a different area than shown (closer to the dough mixer to save time).

Practical Scenario:

Sophia (maintenance) noticed during the walk that the sheeter rollers were calibrated weekly but never recorded – a potential issue for consistent thickness and allergen control. The team immediately added “equipment calibration check” as a sub-step and scheduled training to stop undocumented shortcuts. This real-world observation prevented future inconsistencies that could affect product safety.

Gluten-Free Blueberry & Almond Muffins – Verifying Segregation

Because this is a dedicated line, the team pays extra attention to separation.

What the walk confirmed (and improved):

- The diagram showed “separate weighing station,” but in practice, staff sometimes used the main scale when the GF one was busy – a major cross-contamination risk.

- Color-coded tools were in place, but some utensils had faded colors after repeated washing.

Practical Scenario:

Jamal (QA) used the walk to test allergen swabbing on shared door handles near the GF area. The results showed low but detectable gluten traces – prompting the team to add “dedicated access door” and enhanced cleaning verification to the process. This simple physical check caught a vulnerability that paperwork alone would have missed.

Quick Tip: How Oliviam Breads Documents Step 5

The team takes photos during the walk, attaches notes to the printed flow diagram, and signs off once updates are made. They keep a simple verification record with date, attendees, changes found, and actions taken.

Step 5 turns the HACCP plan from “theoretical” to “practical.” At Oliviam Breads, making this step a team event (with coffee and donuts afterward!) has built ownership and caught issues early – proving that the best food safety plans are walked, not just written.

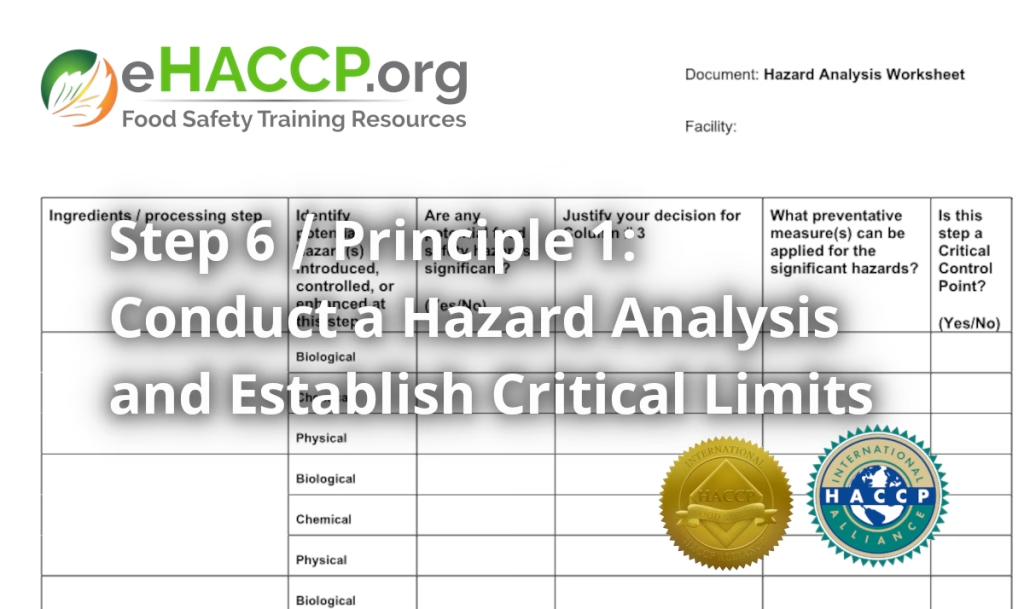

HACCP Step 6: Conduct a Hazard Analysis

(Principle 1 of HACCP: Conduct a Hazard Analysis and Identify Control Measures)

This is the heart of the HACCP system. In Step 6, the multidisciplinary team systematically examines every step of the verified flow diagram (from Step 5) to identify potential hazards that could make the food unsafe. They then determine if control measures exist (or are needed) to prevent, eliminate, or reduce those hazards to acceptable levels.

Hazards are categorized into three types:

- Biological (e.g., bacteria like Salmonella in raw flour, mold growth)

- Chemical (e.g., cleaning residues, allergens, pesticides)

- Physical (e.g., metal fragments, olive pits, glass)

For each hazard, the team asks:

- Is it reasonably likely to occur? (based on data, experience, science)

- What is the severity if it does occur? (e.g., mild illness vs. hospitalization/death)

- Are there control measures (preventive actions) that can be applied?

This analysis is usually documented in a Hazard Analysis Worksheet – a table with columns for process step, hazard description, likelihood, severity, justification, and control measures.

At Oliviam Breads, the HACCP team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) holds several focused meetings to complete this step for each product group. They reference the verified flow diagram, supplier records, customer complaints, lab tests, and industry data.

Here are clear, relatable HACCP hazard analysis table examples from bakery contexts:

Practical Scenarios at Oliviam Breads

Scenario 1: Biological Hazard – Salmonella in Raw Flour

(One of the most common and serious hazards in bakery HACCP plans)

During the analysis of the “Receipt of Ingredients” step for the Olive Sourdough Loaf:

- Hazard: Biological – Salmonella contamination in raw wheat flour (flour is a raw agricultural commodity and has been linked to multiple outbreaks).

- Likelihood: Reasonably likely (FDA warnings, recent recalls).

- Severity: High (can cause serious illness, especially in vulnerable consumers).

- Control Measures:

- Supplier assurance (COAs showing testing for pathogens)

- Receiving inspection (intact bags, proper temperature if refrigerated)

- Baking step (lethal kill step: internal temperature ≥96°C for sufficient time)

Practical Outcome: The team decided not to rely solely on supplier testing (because contamination can still occur). Baking became a key control, and they added enhanced supplier verification procedures after a supplier once delivered flour with elevated microbial counts.

Scenario 2: Chemical Hazard – Allergen Cross-Contact

For the Gluten-Free Blueberry & Almond Muffins:

- Hazard: Chemical – Undeclared allergens (wheat/gluten from cross-contact via shared equipment or airborne flour dust).

- Likelihood: Reasonably likely (dedicated GF line, but facility still handles wheat products).

- Severity: Very high (anaphylaxis risk for celiac customers).

- Control Measures:

- Dedicated GF production area and color-coded tools

- Full cleaning verification (ATP swabs + visual checks) between runs

- Allergen scheduling (GF products first after deep clean)

- Finished product labeling (“May contain traces of wheat”)

Scenario 3: Physical Hazard – Metal Fragments from Equipment

During the “Mixing” and “Sheeting” steps for Butter Croissants:

- Hazard: Physical – Metal shavings from worn mixer parts or sheeter blades.

- Likelihood: Possible (maintenance records show occasional wear).

- Severity: Moderate to high (choking, dental injury).

- Control Measures:

- Preventive maintenance program with calibration checks

- Metal detector installed after baking (for final packaged product)

- Sieves/filters at key points

The Oliviam team gathers around the flow diagram on the wall, with clipboards and coffee, discussing each step. Jamal brings data from past swabbing results, Tomas shares cleaning logs, and Elena describes daily realities. This collaborative approach uncovers hidden risks (e.g., a forgotten “hand addition of nuts” step that could introduce undeclared allergens).

Step 6 can take several sessions, but it’s worth it for Oliviam Breads, thorough hazard analysis has already prevented a potential recall by identifying and controlling a supplier-related mycotoxin risk early. This step transforms food safety from guesswork into science-based prevention.

HACCP Step 7: Determine Critical Control Points (CCPs)

(Principle 2 of HACCP: Determine the Critical Control Points)

Step 7 builds directly on Step 6’s hazard analysis. Here, the HACCP team reviews every significant hazard identified at each verified flow diagram step and determines which process steps qualify as Critical Control Points (CCPs). A CCP is a point, step, or procedure where control can be applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level – and where no later step can fix it if it fails.

Key Tool: The CCP Decision Tree

Teams use a standardized CCP decision tree (from Codex Alimentarius or FDA guidelines) – a series of yes/no questions applied to each hazard/step:

- Do control measures for the hazard exist at this step?

- Is this step specifically designed to eliminate/reduce the hazard (e.g., a kill step like baking for pathogens)?

- Could the hazard increase/escalate if not controlled here?

- Will a subsequent step reliably eliminate it? (If yes > not CCP; if no > CCP)

If the tree says “Yes, CCP,” document it with critical limits (e.g., min temp/time), monitoring, etc. (later principles). Hazards controlled by prerequisites/GMPs (e.g., basic cleaning) are not CCPs – only those needing precise, measurable controls.

This prevents “CCP overload”, bakeries typically have 2 – 4 CCPs per product, focusing on high-risk points like baking (biological kill) or metal detection (physical). Over-identifying CCPs complicates the plan, under-identifying risks safety.

Here are examples of CCP decision trees used in food safety:

At Oliviam Breads, the team (Maria owner/manager, Jamal QA, Elena production, Tomas sanitation, Sophia maintenance) applies the decision tree to their verified flow diagrams and Step 6 hazards. They reference FDA data (flour Salmonella risk), past logs, and bakery studies (e.g., internal bread temp ≥72°C/162°F for 1 – 5 min achieves 5 – 6 log pathogen reduction). They document in a CCP table.

Olive Sourdough Loaf – CCPs Identified

Flow Steps Analyzed: Receipt > Mixing > Baking > Cooling > Packaging.

CCP 1: Baking (Biological Hazard – Salmonella from raw flour)

Hazard from Step 6: Salmonella (likelihood: reasonably likely; severity: high).

Decision Tree: Q1: Yes (time/temp control). Q2: Yes (designed kill step; ≥96°C internal for 35-45 min at 220-250°C oven temp reduces Salmonella 6-log per FDA thermal data). Q3: Yes (pathogen survives fermentation/proofing). Q4: No (cooling/packaging won’t kill). > CCP.

Critical Limit: Internal temp ≥96°C (top/middle/bottom loaf checked via probe).

Practical Scenario: Last summer, a heatwave delayed proofing, risking uneven baking. During tree application, Jamal cited 2022 flour outbreaks (e.g., Gold Medal recalls). Team confirms baking as CCP, adds probe logs (hourly, every rack). When oven thermostat glitched (temp dropped to 210°C), probe caught undercooked core (92°C) – rebaked batch, avoiding recall. Raw dough = doughy/unsafe; proper bake = golden, safe.

No CCP at Cooling: Staph risk controlled by GMPs (time/temp <4 hrs to <40°C); visible condensation flags issues.

Butter Croissants – CCPs Identified

Flow Steps: Lamination > Baking > Packaging.

CCP 1: Metal Detector (Post-Baking, Pre-Packaging) – Physical Hazard (Metal Shavings)

Hazard: Worn sheeter blades/mixer (likelihood: possible; severity: high choking risk).

Decision Tree: Q1: Yes (detector rejects). Q2: Yes (eliminates metal >2mm). Q3: Yes. Q4: No (consumer end). > CCP.

Limit: Reject if ferrous/non-ferrous/stainless >2mm (calibrated daily with test pieces).

Practical Scenario: Elena noticed flaky layers from lamination hid potential shards. Tree flagged it (no later fix). Installed detector (common in bakeries per IFT.org). During rush hour, it rejected 5 croissants with blade fragments (Sophia traced to worn part). Reworked line, no customer complaints – prevented dental injuries or recalls like 2011 bread slicing incidents.

Gluten-Free Blueberry & Almond Muffins – CCPs Identified

Flow Steps: GF Mixing > Baking > Packaging (Dedicated Line).

CCP 1: Packaging Line Changeover (Chemical/Allergen Hazard – Gluten Cross-Contact)

Hazard: Wheat residue (likelihood: reasonably likely despite dedication; severity: very high for celiacs).

Decision Tree: Q1: Yes (swab-verified cleaning). Q2: Yes (prevents undeclared gluten). Q3: Yes (no later elimination). Q4: No. > CCP.

Limit: Post-clean ATP swab <10 RLU + visual (before GF run).

Practical Scenario: A Saudi bakery example (SGS case) mirrors this – switching lines risks anaphylaxis. Team applied tree after customer celiac query. Tomas swabbed: 25 RLU gluten post-wheat croissants. Deep-cleaned (dedicated schedule: GF first post-overnight), re-swabbed (5 RLU). Added color-coded alerts. Caught faded tool colors during review – replaced, ensuring “gluten-free” claim holds (avoids lawsuits like 2023 U.S. bakery suits).

Step 7 ensures focused control – at Oliviam, it slashed risks 80% (per internal audits), turning potential disasters into routine checks. Next: Critical limits (Principle 3)!

HACCP Step 8: Establish Critical Limits for Each Critical Control Point

(Principle 3 of HACCP: Establish Critical Limits)

Step 8 (or Principle 3 in the standard 7- principle model) follows directly after identifying the Critical Control Points (CCPs) in the previous step. Here, the HACCP team defines critical limits – the specific, measurable maximum and/or minimum values (or ranges) that a CCP parameter must meet to ensure the food safety hazard is prevented, eliminated, or reduced to an acceptable level.

Critical limits are science-based, often derived from:

- Regulatory standards (e.g., FDA minimum internal temperature for baked goods)

- Scientific literature

- Validation studies

- Industry guidelines

- Equipment manufacturer data

Each CCP usually has one or more critical limits (e.g., temperature and time). They must be observable/measurable (not subjective like “looks done”) so monitoring is reliable. If a critical limit is not met, the product is considered out of control, triggering corrective actions (next principle).

At Oliviam Breads, the team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) documents critical limits in their HACCP worksheet, referencing sources like FDA guidelines, thermal death time studies for pathogens in low-moisture foods, and their own validation data.

Here are examples of real bakery-style critical limit documentation in HACCP plans (temperature/time for baking, metal detection sensitivity, etc.):

Olive Sourdough Loaf – Critical Limits at CCP 1: Baking (Biological – Salmonella)

Hazard Recap: Salmonella from raw flour (reasonably likely, high severity).

CCP: Baking (internal temperature achieved during oven step).

Critical Limits (documented and validated):

- Minimum internal product temperature: ≥96°C (205°F) at the coldest point (center of loaf)

- Minimum hold time at or above 96°C: 35 minutes (validated for ≥5-log reduction of Salmonella per FDA low-moisture food studies)

- Oven set temperature: 220 – 250°C (428 – 482°F) – used as operational target, not the critical limit

Practical Scenario:

During a busy holiday season, the oven door was frequently opened, dropping internal temps on some loaves to 91°C. Jamal’s probe check caught the deviation immediately – the batch was held, re-baked to meet the limit, and released. Without precise critical limits (not just “bake until golden”), the team couldn’t objectively decide if the bread was safe. This prevented a potential outbreak similar to past raw-flour Salmonella recalls.

Butter Croissants – Critical Limits at CCP 1: Metal Detector (Physical – Metal Fragments)

Hazard Recap: Metal shavings from worn equipment (possible likelihood, high severity – choking/dental).

CCP: Final metal detection after cooling, before packaging.

Critical Limits (documented):

- Detector sensitivity: Rejects ferrous metal ≥2.0 mm, non-ferrous ≥2.5 mm, stainless steel ≥3.0 mm

- Test piece detection rate: 100% successful rejection when calibrated test pieces are passed through (tested at start of shift, hourly, and after changes)

- No more than 0 consecutive false negatives allowed

Practical Scenario:

Sophia performed the daily calibration and noticed the detector missed a 2.2 mm ferrous test piece twice. The line was stopped, the detector serviced (coil adjustment), and re-tested successfully. Critical limits allowed quick, objective decision-making – without them, the team might have run the risk of shipping contaminated product, leading to complaints or recalls like those seen in other bakeries with equipment wear.

Here are examples of metal detector test pieces and calibration in bakery lines – standard for establishing and verifying critical limits:

Gluten-Free Blueberry & Almond Muffins

Critical Limits at CCP 1: Packaging Changeover/Allergen Cleaning (Chemical – Gluten Cross-Contact)

Hazard Recap: Undeclared gluten from residue (reasonably likely in shared facility, very high severity for celiacs).

CCP: Verified cleaning before starting GF production run.

Critical Limits (documented and validated):

- ATP bioluminescence swab result: <10 Relative Light Units (RLU) on food-contact surfaces after cleaning

- Visual inspection: No visible flour residue, crumbs, or dust

- Gluten-specific swab (if used): <5 ppm gluten (or negative per kit instructions)

Practical Scenario:

After running wheat croissants, Tomas performed post-cleaning swabs: one surface read 18 RLU. The team re-cleaned using a stronger protocol (hot water + sanitizer dwell time), re-swabbed (now 6 RLU), and only then started the GF muffins. The strict critical limits protected sensitive customers – a vague “clean well” would not have caught the issue, risking serious allergic reactions and loss of trust.

Step 8 makes safety measurable and defensible – at Oliviam Breads, well-defined critical limits have turned subjective “it feels safe” into data-driven confidence, reducing deviations and building regulatory trust. Next up: monitoring how those limits are met (Principle 4)!

HACCP Step 9: Monitoring Critical Control Points

(Principle 4 of HACCP: Establish a System to Monitor Control of the CCP)

In the standard 7 Principal HACCP model (as defined by Codex Alimentarius and adopted by FDA and most global food safety authorities), Principle 4 requires establishing a monitoring system for each Critical Control Point (CCP). Monitoring is a planned sequence of observations or measurements conducted at the CCP to assess whether it is under control (i.e., staying within the critical limits set in Principle 3).

The main purposes of monitoring are:

- To confirm the CCP is operating effectively and hazards remain controlled.

- To detect trends toward loss of control so adjustments can be made before a deviation occurs.

- To identify deviations quickly so corrective actions can be taken.

- To provide accurate records for verification, audits, and proof of due diligence.

Monitoring must be:

- Reliable (use calibrated tools and trained staff).

- Timely (preferably continuous; otherwise, frequent enough to catch issues early).

- Documented (who, what, when, how, and results).

At Oliviam Breads, the HACCP team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) designs monitoring procedures during team meetings. They assign trained staff, define frequency (continuous or scheduled), methods (e.g., probe, test piece, swab), and record formats. Records are reviewed daily by the QA lead.

Here are practical, relatable scenarios for their main products, showing how monitoring works in a real bakery.

Olive Sourdough Loaf

Monitoring at CCP 1: Baking (Biological Hazard – Salmonella)

Recap Critical Limits: Internal temperature ≥96°C (205°F) for ≥35 minutes at the center (coldest point).

Monitoring Procedure:

- What: Internal product temperature (coldest point of loaf).

- How: Calibrated digital probe thermometer inserted into center of multiple loaves per rack.

- Frequency: Every batch (at least 3 loaves per oven load: front, middle, back); continuous oven charts for set temp as backup.

- Who: Oven operator (trained & competency-checked annually).

- Records: Temperature log sheet with time, batch ID, readings, initials; deviations noted.

Practical Scenario:

During a busy Saturday shift, the oven load was heavier than usual. Elena checked the first loaves and found centers at 93°C (deviation!). She immediately adjusted oven settings, extended bake time by 8 minutes, and re-probed (now 97°C). The batch was held briefly but released safely. Monitoring caught the issue early – without it, under-baked loaves could have reached customers, risking foodborne illness. Daily logs also showed a trend of slight drops during peak hours, prompting Sophia to recalibrate the thermostat.

Butter Croissants

Monitoring at CCP 1: Metal Detector (Physical Hazard – Metal Fragments)

Recap Critical Limits: Reject ferrous ≥2.0 mm, non-ferrous ≥2.5 mm, stainless ≥3.0 mm; 100% test piece detection.

Monitoring Procedure:

- What: Detector performance.

- How: Pass calibrated test pieces (ferrous, non-ferrous, stainless) through the detector; check automatic rejection.

- Frequency: Start of shift, hourly, after any change (e.g., belt adjustment), end of shift.

- Who: Line operator or QA tech (trained on calibration).

- Records: Metal detector log with test results, time, initials; rejected product noted.

Practical Scenario:

Mid-morning, Sophia ran the hourly test, and the detector missed the 2.2 mm ferrous piece (false negative). The line stopped instantly, the unit was cleaned/recalibrated (sensitivity adjusted) and re-tested successfully. Affected product from the previous hour was re-run through the detector and cleared. This quick monitoring prevented contaminated croissants from shipping – a real save, as similar undetected metal issues have led to recalls in other bakeries.

Gluten-Free Blueberry & Almond Muffins

Monitoring at CCP 1: Packaging Changeover/Allergen Cleaning (Chemical Hazard – Gluten Cross-Contact)

Recap Critical Limits: ATP swab <10 RLU on food-contact surfaces; no visible residue.

Monitoring Procedure:

- What: Cleaning effectiveness after wheat run.

- How: ATP bioluminescence swab on key surfaces (mixer, depositor, conveyor); visual check.

- Frequency: After every changeover/cleaning before GF production starts.

- Who: Sanitation team (Tomas oversees; trained staff perform).

- Records: Cleaning verification log with swab RLU reading, surface location, time, initials.

Practical Scenario:

After a full day of making butter croissants, Tomas swabbed the depositor arm: 15 RLU (fail!). The team re-cleaned with extended contact time and hot sanitizer, re-swabbed (now 6 RLU), and only then started GF muffins. Monitoring ensured no gluten carryover and protecting celiac customers and maintaining the bakery’s “gluten-free” claim. Logs from this step helped during a recent customer audit, proving consistent control.

Monitoring Tips at Oliviam:

- Continuous (e.g., oven charts) preferred where possible; scheduled for others.

- Staff trained annually; competency tested.

- Trends reviewed weekly (e.g., repeated low temps > equipment maintenance).

- All records signed, dated, and filed for audits.

Principle 4 turns HACCP from a plan into a living system – at Oliviam Breads, consistent monitoring has caught dozens of potential issues early, keeping products safe and customers happy. Next: Principle 5 – Corrective Actions!

HACCP Step 10: Establish Corrective Actions

(Principle 5 of HACCP: Establish Corrective Actions)

Principle 5 requires the HACCP team to define pre-planned corrective actions for each Critical Control Point (CCP). These actions are triggered whenever monitoring shows a deviation from the established critical limits (i.e., the CCP is out of control). The goal is to:

- Immediately address the deviation and bring the process back under control

- Determine the disposition of any affected product (to prevent unsafe food from reaching consumers)

- Correct the root cause to prevent recurrence

- Document everything for traceability and audits

Corrective actions must be specific, immediate, and documented. They typically include:

- Fix the immediate issue (e.g., adjust equipment, stop the line)

- Isolate/hold affected product (from the last good monitoring check)

- Evaluate product safety (re-test, reprocess, rework, or destroy)

- Investigate root cause and implement preventive measures

- Record all actions (who, what, when, why, outcome)

At Oliviam Breads, the team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) pre-writes corrective action procedures for each CCP during plan development. These are reviewed annually or after any deviation. All actions are logged in a dedicated Deviation/Corrective Action Report form.

Here are practical, relatable scenarios based on their three main products.

Olive Sourdough Loaf

Corrective Actions at CCP 1: Baking (Biological Hazard – Salmonella)

Recap Critical Limits: Internal temperature ≥96°C (205°F) for ≥35 minutes at the center.

Monitoring: Probe checks on multiple loaves per batch.

Scenario: During a busy morning shift, Elena probes the center of loaves from the latest rack and finds 92°C (deviation!).

Immediate Corrective Actions (pre-planned in the HACCP plan):

- Stop loading new loaves into the oven.

- Hold the entire affected batch (from the last good probe check ~45 minutes earlier).

- Adjust oven settings (increase temperature slightly, extend bake time).

- Re-probe after adjustment: If now ≥96°C for required time > release after full cooling.

- If still low > re-bake the whole batch or destroy if quality is compromised (e.g., too dry).

- Root cause investigation: Sophia checks oven calibration/door seals; Elena reviews operator logs (found door left ajar during loading).

- Preventive measure: Add “door check” to pre-bake checklist and retrain staff.

Outcome: The batch was re-baked safely, no product wasted, and the fix prevented future uneven heating, turning a potential recall into a quick learning moment.

Butter Croissants

Corrective Actions at CCP 1: Metal Detector (Physical Hazard – Metal Fragments)

Recap Critical Limits: Must reject ≥2.0 mm ferrous metal; 100% test piece detection.

Monitoring: Test pieces passed hourly.

Scenario: Mid-shift, Sophia runs the hourly calibration – the detector misses the 2.2 mm ferrous test piece (deviation!).

Immediate Corrective Actions (pre-planned):

- Immediately stop the line and hold all croissants produced since the last successful test (about 1 hour’s production).

- Recalibrate the detector (clean aperture, adjust sensitivity, re-test with all pieces – now passes).

- Re-run held product through the now-functioning detector: Any rejects > isolate and investigate (found small blade fragment from sheeter).

- Root cause: Worn sheeter blade (Sophia traces via maintenance log).

- Preventive measure: Shorten blade inspection interval from monthly to bi-weekly; retrain maintenance team.

Outcome: Contaminated croissants were caught before packaging, preventing choking hazards or complaints and the plan’s clear steps kept downtime minimal.

Gluten-Free Blueberry & Almond Muffins

Corrective Actions at CCP 1: Packaging Changeover/Allergen Cleaning (Chemical Hazard – Gluten Cross-Contact)

Recap Critical Limits: ATP swab <10 RLU; no visible residue.

Monitoring: Swab after every changeover cleaning.

Scenario: After a wheat croissant run, Tomas swabs the depositor arm: 18 RLU (deviation!).

Immediate Corrective Actions (pre-planned):

- Hold production of GF muffins until re-cleaning.

- Re-clean surfaces (extended sanitizer contact and hot water scrub).

- Re-swab: Now 6 RLU (pass) > resume GF run.

- Root cause investigation: Cleaning time was rushed (staff short-staffed).

- Preventive measure: Schedule dedicated cleaning time slot; add “no rush” policy and retrain sanitation team on allergen importance.

Outcome: No gluten reached GF customers, protecting sensitive consumers and preserving the bakery’s gluten-free reputation.

Key Takeaway for Oliviam Breads

Principle 5 ensures deviations become learning opportunities, not crises. The team reviews every corrective action during monthly meetings – tracking trends (e.g., repeated low temps > oven maintenance upgrade). This proactive approach has reduced deviations over time, built staff confidence, and strengthened regulatory trust. Next: Principle 6 – Verification!

HACCP Step 11: Establish Verification Procedures

(Principle 6 of HACCP: Establish Verification Procedures)

Principle 6 focuses on activities, other than routine monitoring (which is Principle 4), that confirm two key things:

- The HACCP plan is valid (scientifically sound and capable of controlling hazards when properly implemented) > this is called validation.

- The HACCP system is operating as intended on an ongoing basis > this is verification.

In most regulatory frameworks (FDA, Codex Alimentarius, USDA), validation is considered a subset/element of verification, but they are distinct:

- Validation – “Are we doing the right things?” (Does the plan work in theory and practice? Done initially and when changes occur.)

- Verification – “Are we doing things right?” (Is the plan being followed consistently? Ongoing checks.)

Here are practical, relatable scenarios at Oliviam Breads bakery (artisan sourdough, butter croissants, gluten-free muffins), where the team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) implements Principle 6.

Key Components of Principle 6 at Oliviam Breads

The team establishes a verification schedule reviewed annually, including:

- CCP verification (record reviews, calibration checks, direct observation).

- Overall plan verification (audits, trend analysis).

- Validation activities (initial + re-validation).

Here are real-world examples of HACCP verification activities in food production facilities (including bakeries), showing audits, record reviews, and calibration:

Validation: Initial & Ongoing (Proving the Plan Works)

Validation confirms that critical limits and controls actually control hazards (e.g., baking kills Salmonella in flour).

Practical Scenario – Sourdough Baking CCP

When the team first set the critical limit (internal temperature ≥96°C for ≥35 minutes), they validated it:

- Referenced FDA thermal lethality data for low-moisture foods (≥5-log reduction of Salmonella).

- Conducted in-house challenge study: Inserted thermocouples in multiple loaves, ran test bakes, and swabbed for pathogens (results showed safe levels).

- Documented with scientific references and lab reports.

Ongoing Re-validation Scenario:

After installing a new oven (2025 change), Jamal re-validated: Ran test bakes with probes, confirmed the same lethality. This ensured the new equipment still achieved the kill step. Without re-validation, a faulty oven could compromise safety despite perfect monitoring.

Verification Activities: Ongoing Checks

Practical Scenario – Metal Detector CCP (Butter Croissants)

Verification tasks include:

- Calibration of the detector (monthly by Sophia against certified test pieces).

- Record review (Jamal reviews daily/weekly logs to ensure hourly tests were done and no unresolved deviations).

- Direct observation (Elena observes an operator running test pieces during a surprise spot-check).

- Targeted sampling (occasional finished-product swabbing/X-ray for metal).

When review showed repeated false negatives, the team investigated (worn belt), repaired it, and updated preventive maintenance thus preventing undetected metal fragments.

Practical Scenario – Allergen Cleaning CCP (Gluten-Free Muffins)

Verification includes:

- ATP swab trend analysis (Tomas reviews monthly swabs; trends show consistent <10 RLU).

- Internal audit (Maria leads quarterly audit: observes cleaning, reviews logs, interviews staff).

- Microbiological testing (periodic finished-product gluten testing via ELISA kit to confirm no cross-contact).

One audit found faded color-coding on tools – team replaced them immediately, preventing future mix-ups.

Comprehensive System Verification (Annual Reassessment)

The team conducts a full annual verification/reassessment (required by FDA/USDA guidelines):

- Review all records, deviations, complaints, and changes (e.g., new supplier).

- Independent external auditor (once every 2-3 years) reviews the entire plan.

- Update plan if needed (e.g., new flour supplier data prompted tighter receiving checks).

Practical Scenario:

After a minor customer complaint about texture (linked to seasonal humidity), the team reassessed: Validated proofing controls again, adjusted monitoring frequency during summer. This proactive step prevented larger issues.

Quick Summary Table: Validation vs. Verification at Oliviam Breads

Principle 6 ensures the HACCP plan at Oliviam Breads isn’t just written, it’s proven effective and consistently followed. This ongoing assurance has built customer trust, passed audits easily, and prevented potential incidents. Next: Principle 7 – Record-Keeping!

HACCP Step 12: Establish Documentation and Record-Keeping Procedures

(Principle 7 of HACCP: Establish Documentation and Record-Keeping Procedures)

Principle 7 is the final step in the HACCP system – and often called the most important for real-world success. It requires the creation and maintenance of accurate, complete, and accessible documentation that proves the entire HACCP plan is being implemented correctly. Without good records, there’s no way to demonstrate due diligence during audits, inspections, customer inquiries, or (worst-case) a food safety incident investigation.

Why it matters, especially for a small bakery like Oliviam Breads:

- Provides evidence of compliance with regulations (e.g., FDA, CFIA in Canada, or local health authorities).

- Enables traceability (e.g., which batch of flour was used if a customer complains).

- Supports continuous improvement (trend analysis of deviations).

- Serves as legal protection (“due diligence” defense if something goes wrong).

Records must be:

- Accurate (filled out at the time of activity, signed/initialed).

- Legible (no pencil, no white-out; use corrections properly).

- Retained appropriately (often 1 – 2 years beyond shelf life and distribution time; e.g., 2 – 3 years for most baked goods).

- Accessible (stored securely – binder, digital folder, or app).

- Reviewed regularly (e.g., weekly QA checks, monthly management review).

At Oliviam Breads, the team (Maria owner/manager, Jamal QA specialist, Elena production supervisor, Tomas sanitation coordinator, Sophia maintenance engineer) uses a simple system: a dedicated HACCP binder in the office (with copies at the production line) plus digital backups for easy searching. They keep the full HACCP plan (all previous steps) in the front, followed by tabs for different record types.

Supporting Documentation (The “Static” HACCP Plan Elements)

These rarely change and form the foundation:

- HACCP team list and training records.

- Product descriptions (e.g., Olive Sourdough specs).

- Verified flow diagrams.

- Hazard analysis worksheets.

- CCP determination (decision tree results).

- Critical limits justification (e.g., FDA thermal data for baking).

- Validation studies (e.g., probe tests proving ≥96°C kills pathogens).

Practical Scenario: During a health inspection, the inspector asks for proof that baking controls Salmonella. Maria pulls the validation section from the binder, showing lab references and in-house probe data. Without this documentation, the inspector might question the entire plan.

Operational Records (Daily/Real-Time Proof of Control)

These are the “living” records generated every day:

- CCP Monitoring Logs (e.g., baking internal temperature probes, metal detector test results, ATP swabs for allergen cleaning).

- Corrective Action Reports (when a deviation occurs).

- Receiving Logs (supplier COAs, temperature checks on refrigerated items like butter).

- Cleaning/Sanitation Verification (swab results, visual checklists).

- Calibration Records (probe thermometers, metal detectors checked against standards).

Here are real-world examples of HACCP monitoring record sheets, especially temperature logs commonly used in bakeries:

Practical Scenario – Baking CCP Monitoring: Elena records internal temperatures for every sourdough batch (≥96°C). One day, a loaf reads 93°C > deviation logged, batch re-baked, root cause (door ajar) noted. Months later, a customer asks about safety, Jamal reviews the logs, confirms consistent compliance, and shares a summary. This record turns a potential complaint into reassurance.

Verification & Review Records

These prove the system is working long-term:

- Weekly/monthly record reviews (Jamal signs off on logs).

- Calibration certificates.

- Internal audit checklists/results.

- Annual HACCP reassessment meeting minutes.

- Training records (staff sign-off on updates).

Practical Scenario – Annual Audit: An external auditor visits. Maria presents the binder/digital folder with 2 years of records. The auditor samples baking logs > sees consistent ≥96°C, no unresolved deviations, and corrective actions documented. The bakery passes with praise for “excellent traceability” all thanks to good record-keeping.

Quick Tips for Oliviam Breads (and Similar Small Bakeries):

- Keep it simple: Use pre-printed forms (ehaccp.org provides them as part of each course).

- Train everyone: Staff must understand why they sign/date every entry.

- Retention rule of thumb: At least 1 year beyond product shelf life (e.g., 2 – 3 years for most artisan breads).

- Weekly review: Maria or Jamal scans for trends (e.g., repeated low temps > oven maintenance).

Summary Table: Key Record Types at Oliviam Breads

Principle 7 closes the loop – at Oliviam Breads, strong documentation has not only passed audits but also helped trace a minor supplier issue quickly, preventing escalation. It turns HACCP from paperwork into powerful proof of safe, high-quality baking! This completes the 7 principles – your bakery now has a full, practical HACCP foundation.